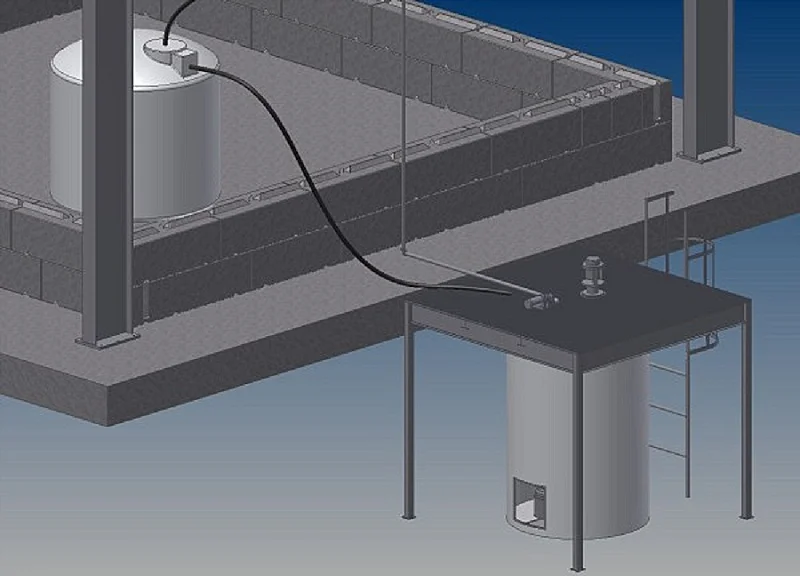

Columbia Energy designed and constructed a full scale transfer pump and piping mock-up, a double-shell tank (DST) mock-up, and performed a full-scale limits of performance (LOP) demonstration.

Columbia Energy tested the mobilization of settled solids and pumping of slurries. We focused on high density, large-sized solids, which impose design constraints on agitation and pumping systems. Columbia Energy also tested the associated transport piping beyond those applicable to straight liquid transport designs.

The test considered Slurry Transport Effects on Pump Performance with the pump size (smaller diameter pumps incur larger performance impacts), particle diameter, particle shape, and particle versus fluid relative density.

The test also considered: Stratified Solids Flow in the Slurry Transport Pipeline. Tests were performed on the re-suspended solids in the pipeline which required more pumping energy (head and flow) than transporting them once they are moving.

Services

- Engineering and Design

- Procurement of NQA-1 Simulants

- Fabrication

- Construction

- Testing

- Documentation

Design Features

- Full-scale mock-up of piping system

- Mixing system development and modifications

- Re-use of existing equipment to lower cost

Stakeholders

- U.S. Department of Energy (DOE)

- Office of River Protection (ORP)

- Defense Nuclear Facilities Safety Board (DNFSB)

Specifications

- B31.3 Piping

- Instruments calibrated with NSIT traceable certifications of calibration

- Newtonian and non-Newtonian slurry simulant transfer and slurry mixing

- Solids retention and measurement